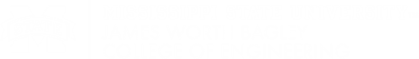

Billy Peacock, associate director of CAVS-Extension, delivered a workshop to show manufacturers how to manage work more efficiently, visualize workflow, and analyze and improve their business processes using kanban. Kanbans were first developed and applied by Toyota as a scheduling system for just-in-time manufacturing based on customer demand to produce goods and push them to the market. Kanbans are used to connect customers to suppliers, with the purpose of minimizing waste and maximizing production activities. In the simplest form, the system communicates what is needed, when it is needed, and the quantity needed. Kanbans are used as part of a "Pull System" to help facilitate a smooth, steady pace of information to upstream processes and can be used for "pulling" from internal suppliers, or from external suppliers, and do not require complex or expansive ERP (enterprise resource planning) systems.

For more information about Kanban, contact Billy Peacock at bpeacock@cavse.msstate.edu, or at 601.407.2767, or visit the CAVS-E website at cavse.msstate.edu