Whether it is support for lean manufacturing concepts, improving the efficiency of operations, or providing insight into new designs, simulation is a key technology for addressing complex problems and a tool used to analyze and solve real-world issues in today's challenging business environment. Simulation software is commonly used for determining levels of operational excellence and cost reduction. FlexSim software is one of the most powerful and effective simulation tools on the market today, a problem-solving mechanism designed to make simulation easy to analyze and to optimize any system in any industry. FlexSim is a user-friendly and interactive program that allows users to build and customize projects of any scope or complexity. It is capable of using commands as building blocks to represent material or customer flow and produce standard output statistics, such as production and wait times, or custom performance measures set by the user. It also has a graphical display to help visualize product flow and identify bottlenecks. FlexSim takes a traditional approach to simulation using three-dimensional image processing technology and detailed models that deliver results and make an impact in validating and improving processes. FlexSim simulation applications can be used in healthcare, manufacturing, and service delivery, and can be applied to a variety of processes, such as production, inventory management, purchasing, and even gaming. 'Simulation Modeling and Analysis Using FlexSim' supports a fresh approach for teaching simulation through logic and task execution activities using organization and application techniques, and blending theories with practices.

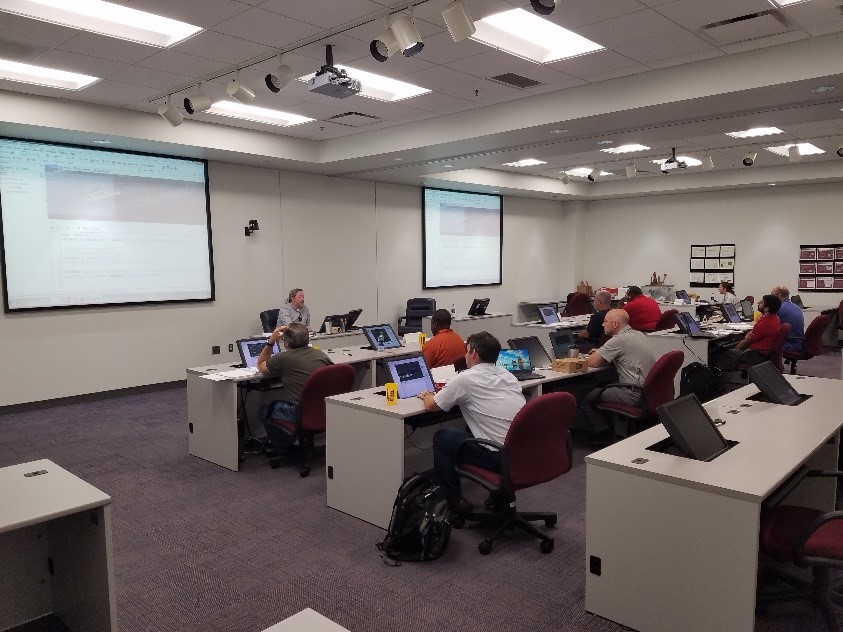

The Center for Advanced Vehicular Systems Extension offers a 'Simulation Modeling and Analysis Using FlexSim' workshop that is structured so participants can learn how to navigate through FlexSim's modeling environment and apply the FlexSim modeling techniques that are used by simulation experts. Workshop participants are given the opportunity to use simulation concepts in developing their own project model, conducting an analysis that addresses any issues, and presenting their findings. Participants are able to interact on a one-on-one basis with CAVSE instructors to facilitate their "real" models. The workshop addresses a variety of subjects, such as how simulation modeling and analysis (SMA) can improve organizational performance, and provides the basics in FlexSim modeling, coding, data input, importing and exporting MS Excel data, and interpreting outputs in FlexSim, as well as a host of other advanced topics, including custom user commands and task sequences used in the process.

Adam Collins, CAVSE research engineer and FlexSim workshop instructor, states that, "CAVSE offers the Simulation Modeling and Analysis workshop to help companies develop the skills to use one of the most powerful tools in proactive process improvement as a means to achieve operational excellence. Change is expensive, and often cost- or time-prohibitive to modify after implementation. Understanding the impact on the system performance before investing limited resources is the key to remaining competitive." By developing simulation projects, building models, and monitoring real-time systems with FlexSim, participants obtain greater insight and knowledge about their current processes and learn how to utilize simulation most effectively.

To learn more about the programs and services offered by CAVS-E, visit cavse.msstate.edu.